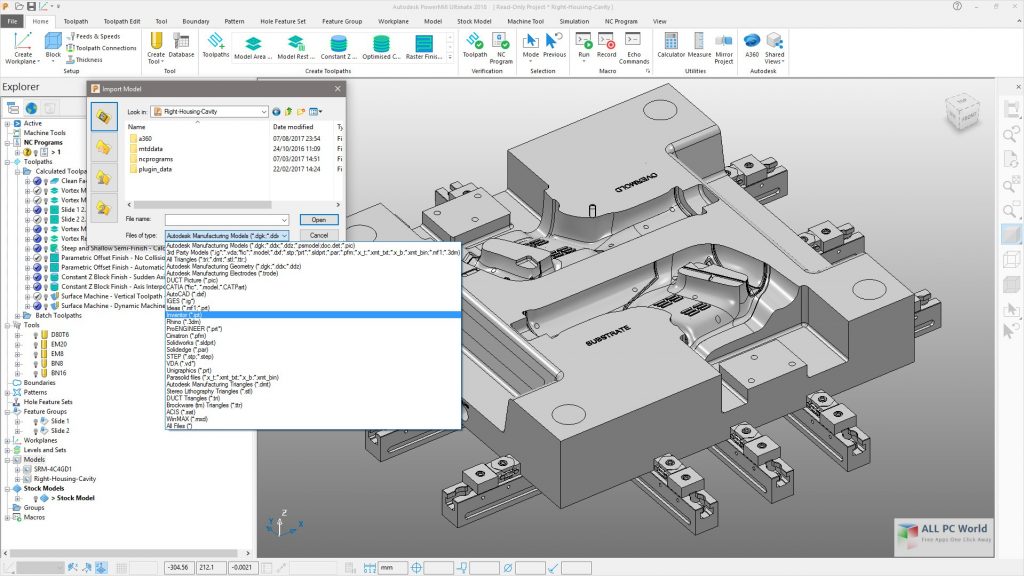

Users can also turn to third-party simulation packages that feature more accurate and sophisticated G-code simulations. Most CAD/CAM systems offer a basic level of simulation, based on cutter location (CL) data. Today’s simulation tools offer a variety of ways to prevent such costly programming errors. Ensuring top quality means using high-fidelity simulations to set up the cut. Even a minor error in, say, a titanium aerospace component can be a major expense. Manufacturers must avoid costly machine errors that cause catastrophic damage to both machine tools and expensive workpieces. The Hawk Ridge team was able to help them bridge the gap with CAMWorks and Eureka, allowing them to simulate complex programs from multiple CAM systems and get programs efficiently to the shop floor.The latest simulation packages offer CAD/CAM and NC-level code-checking to ensure fast, error-free machining processes The Reviewer App in VERICUT illustrates a program showing that the machine spindle will collide with the part during the process. They were also looking to add new equipment, including a twin table 5 axis mill.

#Cnc simulator online software

From a company that is just starting out in CNC manufacturing and getting familiar with their new investment, to an experienced shop that wants to expand into more complex machining, we help them implement Eureka machine simulation to get them up-to-speed with new equipment faster and gain the confidence to run programs knowing they are right the first time.

#Cnc simulator online code

The software converts APT code generated by a CAM system into a program for a 6 or more axes robot cell using a dedicated post-processing module. Eureka performs simulation based on a highly accurate and reliable “digital twin” of the machine tool and CNC controller, allowing programs for any machine to be prepared, simulated, and verified even in the absence of the real machine.Įureka Robot combines the flexibility of a 6 axis robot with the technology of CNC machine centers. It simulates the actual G-code regardless of how it was created. It also allows you to avoid the risks of damaging expensive work pieces, breaking tools, and collisions with machine parts such as the spindle, caused by programming errors.Įureka G-Code is a leading NC simulation software for any CNC machine. You can do all the tests you want, quickly, without taking your machine out of production. Increase CNC Machine Productivity and Avoid CollisionsĮureka software allows you to have a digital replica on your computer of the machines in your workshop.

0 kommentar(er)

0 kommentar(er)